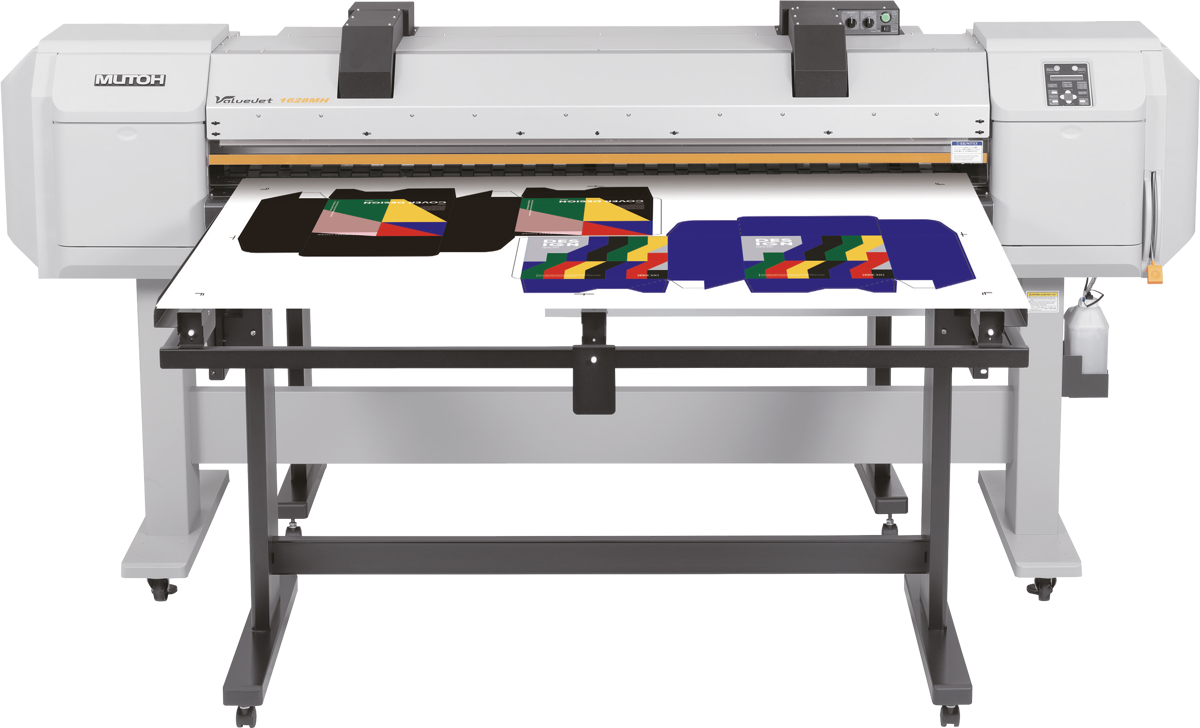

Real Substrate Proof can shorten the time-to-market and reduce press proof cost by delivering packaging proofs that cannot be distinguished from the original print.

Unlike other suppliers of packaging proofs Real Substrate Proof can print on the original media and retain the look and feel and all other physical properties of the final print.

“MP31 ink” is similar to eco-solvent ink in “weather resistance”, “abrasion resistance” and “color development “, and yet it produces smooth and natural finish preserving the texture of the print substrates.

It is also tough against heat and elongation, and the printing surface is not easily broken even when bent. “MP31 ink” can be used to print and process on the materials for vacuum moulding and thermoforming materials.

Allows packaging professionals to check the correct distortion of a shrink sleeve prototype thanks to the fact that the new XG INKS have unique stretch and shrink capabilities

Covers exactly the proofing applications for which transfer film and traditional water-based, eco-solvent and UV inks are not the best alternative.

Our new inkset has an extremely wide colour gamut consisting of CMYK, orange, green, blue and white. Essential and unique for Real Substrate Proofing.